- +38 066 411-51-45

Inspection of all-metal knife №1

Overview:

I chose the all-metal №1 knife for testing in the knife workshop of masters Kulbida Lesyuchevsky in Irpen. For more than a year he took part in various expeditions, autonomous companies, worked on a cutting board and now it's time for a photo text review. I admit that it was possible to choose any serial model, although manufacturers usually choose the models for testing. I chose this model and another knife, which I will introduce later. The choice was based on the relatively small size of the knife compared to other processing and hunting swords and comfortable ergonomics.

All-metal knife, which is an undeniable advantage over other types of knives in practicality and reliability. The polished blade is made of S30V powder steel like Drop-Point with a decrease in the butt line. It has a flat-concave wedge with a feed of 30 ° and a straight, smooth cutting edge of the blade with a hardness of 59-60 units. The advantages of this form of cross-section are, above all, the manufacturability of its production and therefore lower production costs. In addition, such blades are easier to sharpen and even with repeated grinding long retain the same thickness of the cutting edge.

Behind the butt is a small smooth stop for the finger, which improves the quality of the grip during prickly movements. On the side of the main blade at a small angle is the limiter for the same purposes as the stop, only it, depending on the grip, rests on the index finger or little finger.

The knife is monolithic, so the shank is a handle. This is very practical, because in case of destruction of the pads, you can use others, both industrial and homemade: lace, fabric, bandages. The handle has a complex ergonomic shape with a rectangular cross section and two recesses under the fingers. The end is ergonomically extended to support the index finger or little finger, depending on the grip, and has a hole for the sling or safety cord. Handle material - cocobolo. Cocobolo is a tree that belongs to the rosewood family and grows in Mexico. This is one of the strongest species of trees, it is very difficult to handle. Cocobolo wood sinks in water. Despite the difficulties of processing cocobolo is very popular around the world primarily due to its good texture and strength. The material is polished almost to a mirror state and remains smooth and shiny for a long time. The overlays are connected by special branded rivets, which are an excellent element of the design of these masters.

The knife is designed mainly for finishing and household work of small complexity. Dimensions: blade length - 125 mm, butt thickness - 4 mm, handle length - 125 mm. Weight: 160 g.

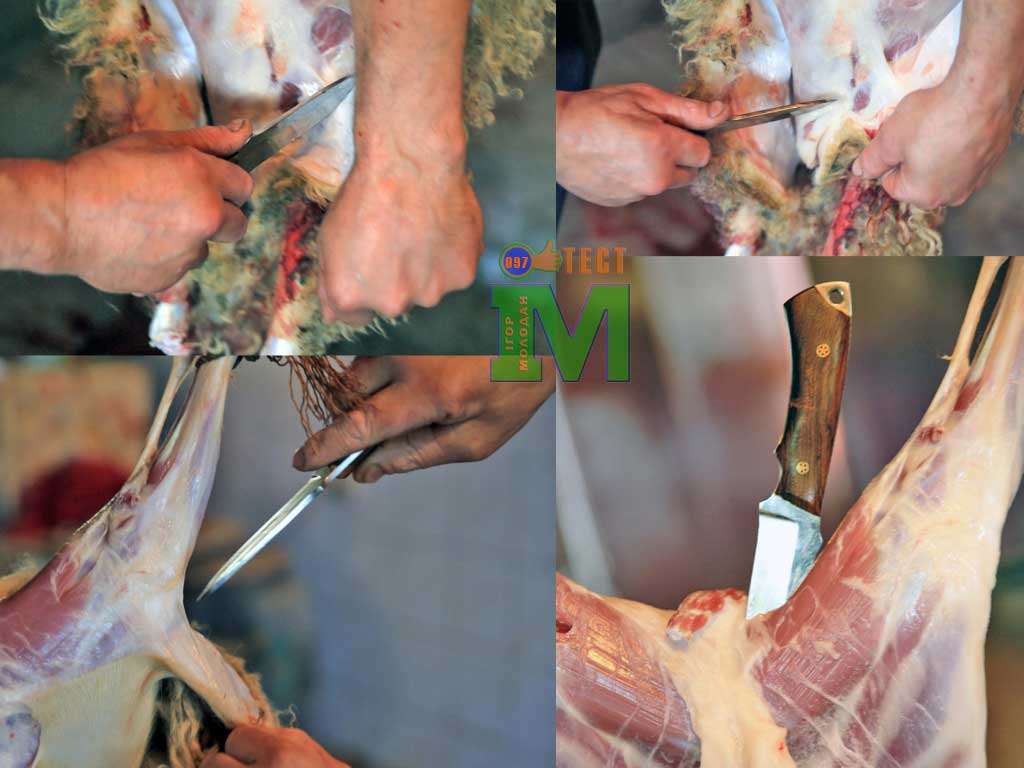

Test:

The grip of the knife is very convenient. In fact, this is the second main criterion after the size by which I selected knives for testing in the workshop of craftsmen. Both the straight and the back grip approached my medium-sized palms. Perhaps more pronounced emphasis will add confidence, but they will change the whole look. The knife sits securely in the hand, and work with them in any direction and position is quite comfortable.

Currently, powder steels are often used in the manufacture of hunting knives, as their properties allow you to use a blade for processing carcasses and not be afraid that it will quickly blunt. Blades made of this steel rarely break and do not break off pieces under rough mechanical impact. However, with its hardness, the knife is quite difficult to correct, so you can not fail by improvised means, this requires grinding devices. Despite its excellent cutting properties, steel is fragile. Knives made of this material are not recommended to throw into trees, throw, test for bending.

After working with a knife, especially in acid-alkaline environments (cutting lemon, getting into salt water, etc.) it should be washed thoroughly, otherwise dark spots may appear. The steel itself is stainless, but if not cared for properly, it is guaranteed to be covered with an unpleasant plaque, which is removed only during polishing.

The knife is equally easy to open canned food, cut bread or cut the cord. They can process wood and use it for simple economic purposes. You can even cut branches and small trunks of trees, split logs, using a die that hits the butt, but this should be done carefully, remembering that the steel is fragile.

The penetrating properties of the knife are not high. It is unlikely to work effectively to slaughter the beast. The main purpose of the knife - carcass processing. In this he is an incomparable leader in relation to other functionalities. A knife sharpened for shaving is able to process more than a dozen sheep carcasses without bringing the blade, which is quite a good figure. It should be noted that excessive hand tension was not felt, but it all depends on the size of the palm and the comfort of the grip.

Conclusions. All-metal knife №1 performs its functionality, while being very comfortable, high quality and ergonomic. Perfect for both household and camp work, including the processing of animal carcasses.

Recommendations:

Make a notch on the finger rest and end, which is quite effective if the user is wearing gloves.

Source: http://avtonom.club/test-tsentr.html/nozh-tselnometallicheskij-1/